Powerful, Easy-to-Use, Lightning-Fast

SPC and CMM Data Collection Software

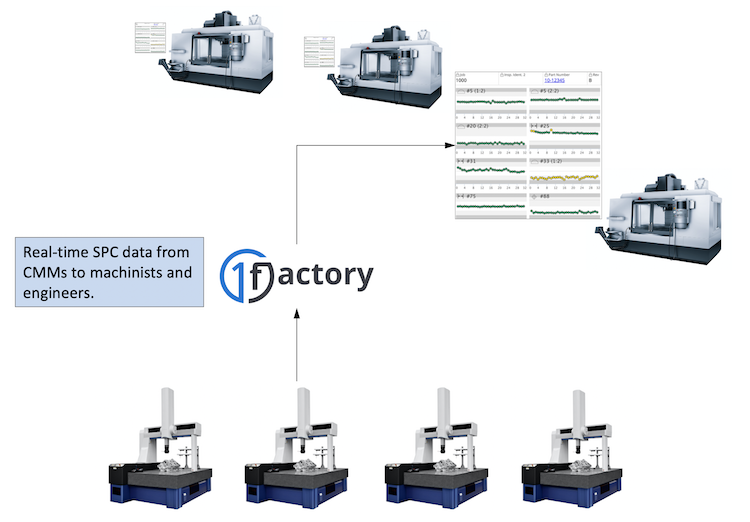

Automate data capture from coordinate measuring machines (CMMs), vision systems, and other inspection equipment. Load data in seconds and deliver real-time SPC charts to factory-floor users so they can correct manufacturing processes, address drift and prevent defects.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & INDUSTRIAL

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS

AUTOMATE CMM & VISION SYSTEM DATA COLLECTION. DETECT PROBLEMS EARLY.

EFFICIENCY & COST SAVINGS

“Overall, I am very happy the implementation of the 1Factory software. Our operators love the ease of use, and the fact that they no longer have to transfer CMM data by hand.”

Harrison M., Quality Engineer

OVERVIEW

WHAT IS CMM DATA COLLECTION?

Modern manufacturing quality control relies heavily on precision measurement equipment - from CMMs and vision systems to profilometers and digital gages.

Each measurement device generates critical dimensional data that must be analyzed for process stability and compiled into customer reports.

WHAT MAKES CMM DATA COLLECTION CHALLENGING?

Manufacturers face mounting complexity in collecting and analyzing measurement data across diverse equipment types.

CMMs present particular challenges, with each machine outputting data in proprietary formats and handling GD&T results and multi-place dimensions differently.

THE 1FACTORY CMM DATA COLLECTION SOLUTION

1factory transforms measurement data collection through intelligent auto-upload capabilities that connect directly to CMMs and other measurement devices.

Our platform automatically interprets diverse data formats and instantly generates live SPC charts and process analysis.

FEATURES

1Fully Automated CMM Data Import

Fully automate data collection from CMMs, Vision Systems, and connected digital gages. Data is imported as soon as the CMM outputs the file. Supported devices include Zeiss, Keyence, PCDMIS, Mitutoyo and many more.

2Select and Upload CMM Data Import

Partially automate CMM data import. Import data by selecting CMM output files. Load data for one part or multiple parts. Load either (1) one file per measured part, or (2) multiple files per measured part.

3Multi-Parameter SPC

Instantly generate live SPC charts and enable real-time control of critical features. Detect trends and anomalies quickly at the point of manufacture. Notify engineers and managers of out-of-control events.

4Tabulated Plans

Easily manage tabulated drawings with thousands of configurations via a single Inspection Plan for the family. 1factory automatically generates the inspection sheet for each configuration.

CASE STUDIES

Read Highlights & Transcript

Highlights: CMM Automation & SPC Success at UMC

- Challenge: Automating the output of 30 CMMs into a centralized system in real-time.

- Automation: UMC consolidated 5 separate software systems into 1factory, achieving Fully Automated CMM Data Import.

- Volume: The system manages 100 to 800 features per part, processing over 1 million data points monthly.

- Visibility: Every data point from a CMM probe or vision scan is visible instantly to machinists on the shop floor via Real-Time SPC Charts.

- Training: Technicians required only 15 minutes of training to start using the system effectively.

Transcript Excerpt: "OK, prove it. That was the gauntlet thrown down by UMC... once the inspection data is in 1factory, the software creates a run chart and histogram that shows which part features present the highest risk of failure".

Ultra Machining Company (UMC)

Ultra Machining Company (UMC) is a manufacturer of high-precision components for medical device, aerospace, and defense applications. Products manufactured by UMC are complex, with 100 — 800 features per product. UMC's Quality Control team operates nearly 30 CMM and Vision Systems.

"OK, prove it. This was the gauntlet thrown down by UMC to 1Factory - a challenge to automate the data output of nearly 30 CMMs straight into 1Factory in real time."

"This capability means that every data point from every touch of a CMM probe or scan of a vision machine is visible almost instantly to every machinist at every workstation on the shop floor. Once UMC's inspection data is in 1Factory, the software analyzes the data and creates a run chart and histogram that shows which part features present the highest risk of failure."

Read the full Modern Machine Shop Feature on 1factory's work with UMC.

EASY TO USE. LIGHTNING FAST. SECURE & RELIABLE

INTUITIVE DESIGN & SPEED

1Factory's intuitive interface makes training effortless - most teams achieve full deployment in under two hours with zero operational disruption.

Speed is non-negotiable on the shop floor. Every interaction happens instantaneously. Your operations run at full pace, never waiting on software.

SECURITY & RELIABILITY

ITAR-compliant hosting on AWS GovCloud, full NIST 800-171 compliance, and SOC 2 Type 2 certification. Your quality data stays protected.

Over the past decade, 1Factory has maintained >99.99% uptime. Data encryption and daily snapshots ensure your records are always recoverable.