Case Studies: Extraordinary Results. In Weeks, Not Years.

rms | Cretex Medical Company

rms | a Cretex Medical company is a leader in medical device manufacturing for the Interventional, Cardiac Rhythm Management, and Orthopedic markets.

"Quality is paramount at rms.", John Braun, President.

When rms set out to replace their legacy systems, they sought a partner capable of meeting their challenging requirements, along with ease of implementation, ease of use, and scalability.

In just one year, rms successfully deployed 1factory for: 4 manufacturing sites, 900+ machine-tools, 1300 users and 100+ CMM / vision systems.

rms created 21,000+ Inspection Plans, inspected over 70,000+ Lots, recorded 12 million+ Data Points and consolidated 6 QC systems into one.

Watch a 5-min video to hear first-hand experiences from the cross-functional rms team: Machinists, Quality Engineers, Quality Managers, Project Manager and President.

Read Highlights & Transcript

00:00 - Introduction & Mission: John Braun (President) discusses why product quality is paramount at rms. "Quality is the number one thing we sell. We have to have the best quality systems in the world."

00:50 - The Problem: The team compares the legacy paper-based and fragmented systems with the new 1factory deployment, highlighting the inefficiency of the old way.

01:28 - Consolidation Success: "We were able to move from 6 different software systems to a single all-in-one QC software system."

02:00 - User Experience: Machinists and Quality Engineers highlight the intuitive interface. "Training new employees takes a fraction of the time it used to. It's very easy to learn."

03:15 - Scalability & Performance: Discussion on how 1factory handles the immense volume of 900+ machine tools and millions of data points annually without slowing down production.

Conclusion: "1factory has been a true partner in our growth, allowing us to scale without sacrificing quality."

Avalign Technologies

Avalign Technologies is an industry leader in the design and manufacturing of high-precision implants and instruments for orthopedic, spine, and trauma applications.

The Challenge: Avalign needed a comprehensive Quality Control solution that delivered: Robust capabilities, Enterprise-grade security, Seamless scalability, Intuitive user experience, and Initial and on-going validation

"There are thousands of software suppliers to select from. And during the sales cycle you often find that the relationship is terrific, but then it falls apart very quickly after you sign the contract. With 1factory, they stayed with us every step of the way, and they continue to partner with us into our future." - Robin H., CIO

Watch a 4-minute video to hear first-hand from the Avalign team about their experience with 1factory.

Read Highlights & Transcript

00:10 - CIO Perspective: Robin H. explains, "It's been just a tremendous timesaver for us and it also has really helped us with having the right data at the right point."

00:44 - The Evaluation Process: Avalign evaluated software based on Capability, Security, Scalability, Ease-of-Use, and Validation support.

01:10 - Seamless Onboarding: Implemented within weeks, not months. A smooth transition for the entire team.

01:56 - CMM Automation: CMM Program Data Auto Upload saves time and ensures the right data is available at the right time.

02:19 - Validation & Compliance: "As a medical device manufacturer, we are required to comply with FDA validation requirements. With 1factory, they really do such a phenomenal job at their validation testing and documentation. That's eliminated a lot of the burden on our team."

02:45 - Competitive Advantage: "Now that we've been using 1factory for 2 years, it helps us gain a competitive edge. When customers come in, we can pull up their product right there and show our trend charts."

03:30 - True Partnership: "There are thousands of software providers... with 1factory they stayed with us every step of the way and they continue to partner with us into our future."

Ultra Machining Company

Ultra Machining Company (UMC) is a manufacturer of high-precision components for medical device, aerospace, and defense applications. The products are complex, with 100 - 800 features per product.

With 1factory, UMC successfully consolidated 5 separate QC systems into 1.

Today, data is automatically uploaded from 20 CMMs and 8 VCMMs, 24 hours a day. Over 1 million measurements are recorded in 1factory each month. Auto-ballooning speeds up FAI creation. And hours are saved from each PPAP package creation.

Read the Modern Machine Shop Feature on 1factory's work with UMC.

Watch a 4-minute video to hear first-hand experiences from the cross-functional UMC team: Machinists, Quality Engineers, Director of Quality, VP of IT, and VP of Operations.

Read Highlights & Transcript

00:00 - Introduction to UMC: An overview of Ultra Machining Company and their complex components for medical and aerospace sectors.

00:30 - The Need for Modern QC: "The old systems were very slow... it was often faster to do work manually than use the system." They couldn't handle 800 parameters per part or 1 million data points per month.

01:10 - Rigorous Selection: UMC evaluated 12 vendors against 145 specific requirements before selecting 1factory as the winner.

01:40 - Major Achievements: "With 1factory, UMC eliminated 5 different pieces of software." Data entry and chart refresh are now instantaneous, replacing laggy legacy systems.

02:33 - Training & Use: Technicians required only 15 minutes of training to get started.

03:00 - Machinist Feedback: "Real-time feedback from CMM to machinist allows process corrections immediately."

Conclusion: Paper and Excel files have been completely eliminated from the QC activities on the factory floor.

Zipline

Zipline designs, manufactures and operates the world's largest autonomous delivery system, delivering life-saving supplies such as blood and medicines, and cutting delivery time from hours to minutes.

High-quality parts are critical to reliable flight and delivery of life-saving supplies.

To ensure the quality of parts coming in from suppliers, Zipline deployed the 1factory system across its supply chain. Today suppliers create Control Plans and First Articles and submit them to Zipline for review and approval via 1factory. Once Plans and FAIs are reviewed, suppliers submit on-going inspection data to Zipline via 1factory.

Watch a 7-minute video to hear first-hand from the Zipline team (Incoming Inspection, Quality Engineering, Supplier Quality, and Chief Technology Officer) about the power of 1factory, its ease-of-use, and its impact on cost of quality.

"1factory is the best SaaS software Zipline uses" - Keenan W. CTO.

Read Highlights & Transcript

00:00 - About Zipline: Discussion on why product quality is critical to successful autonomous delivery operations. "We deliver life-saving supplies within the exact minute."

01:50 - Supply Chain Complexity: Managing 1,000 unique parts for the drone and 5,000 for the ground system from global suppliers.

02:28 - Solving the "Stale Data" Problem: "We are solving the problem of stale and dusty control plans, and lack of supplier monitoring of quality data. 1factory has enabled a different level of integration with our key suppliers on high risk parts."

04:12 - Ease of Use: The product is extremely easy to use; suppliers were trained in under 2 hours.

05:08 - Supplier Perspective: "With 1factory, we give the customer access to the heart of our quality data. Everything is available and that gives the customer security. It saves us a lot of paperwork."

07:26 - CTO Testimonial: Keenan W. states, "1factory is the best SaaS software Zipline uses. It's rare to find software that is this powerful yet this easy to use."

Next Intent

Next Intent is a world-class precision manufacturer, serving the space, defense, aerospace and semiconductor industries. The parts they craft are critical to the success of billion-dollar, multi-decade missions - where a single failure isn't just costly, it's catastrophic.

Notable projects include components for THREE Mars missions, and the revolutionary Red Camera Assembly for the Giant Magellan Telescope and more.

Next Intent picked 1factory to meet its challenging quality requirements. With 1factory, Next intent has unified quality planning, inspections, gage managements, and quality records into one seamless ecosystem, automating paperwork, eliminating errors, and helping deliver the highest quality parts to customers.

"The Software worked just like the demo!" - Rodney B., President & CEO

"We were going to go with another company's software. The implementation time was nine months. That was too long. With 1factory, they were getting it to work within the first day. Within twenty minutes, I had bubble-printed the plans and inspection sheets." - Cliff M., Quality Manager

Read Highlights & Transcript

00:00 - About Next Intent: Producing mission-critical components for Mars rovers and the Giant Magellan Telescope.

00:35 - Why 1factory: "We were about to place an order for a competitor's product that was expected to take 9 months to install. In contrast, 1factory promised they would be live in one day. And they delivered."

01:15 - "Just Like the Demo": Rodney B., CEO, confirms the software worked exactly as promised, with no hidden complexities.

01:20 - Instant Productivity: "Within 20 minutes, I had bubble-printed the plans and inspection sheets."

01:46 - AS9102 Success: Over 500 First Article Reports (AS9102) completed. "We cut FAIR reporting time from hours to minutes."

02:04 - Collaboration: Improved collaboration within the factory, unified quality planning, and eliminated errors in paperwork.

VIDAR | ITT Company

VIDAR (an ITT Company) manufactures advanced industrial motors with embedded variable-speed intelligence for critical sectors like chemical processing, water, and energy.

VIDAR faced challenges with a fragmented, paper-based Quality Management System (QMS) that resulted in slow production and burdensome audit preparation.

The new digital QMS reduced audit preparation time by 83% (from 3 days to 4 hours).

Document retrieval time plummeted from 15 minutes of searching to under 1 minute, unlocking time savings across every search query.

Supplier Corrective Action Request (SCAR) closure time dropped by 70%, positioning VIDAR for ISO 9001 certification.

"It takes all the complexity of compliance, documentation, and process control and makes it as straightforward as flipping a switch", Tony Sonson, Director of Operations.

Wilcox Industries

Wilcox Industries is a leader in high-precision tactical solutions for military and law enforcement, specializing in Night Vision and Combat Systems. To meet the rigorous demands of mission-critical components, Wilcox needed to centralize its quality data and streamline its demanding AS9102 and FAI processes.

With 1factory, Wilcox established a single source of truth for all inspection records and documentation. The system unified quality planning and manufacturing data, leading to a significant increase in data confidence, eliminating reliance on paper processes, and ensuring immediate audit-readiness.

"What does 1factory now make possible for you?" "It allows us to do [quality control] as a team. So, every player at Wilcox has a part, and they're able to input their data, have that traceability to the data to show that every part we produce meets customer requirements and that it's safe." Dan L., Director of Quality

Watch the full video to hear first-hand from the Wilcox team about their digital quality transformation across manufacturing and incoming quality.

Read Highlights & Transcript

00:18 - Introduction: Dan L. (Director of Quality) introduces Wilcox and emphasizes the "Quality Culture" where customers' lives depend on the product.

01:09 - The Old Way vs. 1factory: "We had handwritten drawings, excel sheets, and cumbersome systems."

01:25 - Immediate Impact: Inspection time reduced significantly. Inspections are now more robust, and data is centralized.

01:56 - Ease of Use: Onboarding process, standardization of work, and ease of training for new hires.

02:29 - Automation: "Automated CMM and Vision System Data Collection allows for immediate data availability."

04:15 - Gage Management: Ben discusses the inspection and Gage Management system. "It allows us to know exactly where our gages are."

06:24 - Speed of Change: "From design to manufacturing in minutes vs days."

07:26 - Incoming Inspection: Jen discusses incoming inspection with 1factory, optimizing with feature-level AQLs and building a supplier quality system from scratch.

09:33 - Conclusion: "Would you ever go back to the old way? No."

Allegheny Performance Plastics

Allegheny Performance Plastics manufactures advanced parts and assemblies from high-performance polymers for the space, aerospace, defense, and transportation industries.

Allegheny made the switch to 1factory and saw immediate benefits, including the ability to see SPC data in real time versus days later after bulk uploading in the old systems.

Since adopting the software, the company says the biggest savings in time and resources have come from ending manual transposing and navigating multiple systems to retrieve quality information.

Allegheny's customers are able to view a live feed of their jobs via 1factory's Deep Collaboration feature, including all SPC and process capability calculations. This level of transparency is unprecedented and has helped their build customers' confidence in their capabilities.

Eskridge Inc

Eskridge Inc designs and manufactures application-specific gear drives for aerospace, farming, energy, marine, industrial, and other applications.

Eskridge has to ensure quality for nearly 900 different Gear Drive component made in-house and 500 components from across their supply chain.

With 1factory, Eskridge was able to communicate requirements to operators, ensure data was being collected, and was able to significantly reduce scrap and rework.

Read the full case-study along with the Eskridge team's insights into how consistent quality gives them a competitive edge.

Fairview Machine

Fairview Machine is a manufacturer or high precision Aerospace and Medical components. Fairview Machine deployed the 1factory quality control and quality management (QMS) system and digitized their QC processes.

"Within the first week, our machinists began to come into the quality department asking when their (inspection) jobs would be running with 1factory."

"I would 100% recommend the transition to 1Factory's QMS. It has helped Fairview go completely paperless over the past 3 years while helping us maintain exceptional traceability across the board.", Harrison Moulton, Quality Manager.

Read the full case-study to learn how Fairview Machine transitioned the entire organization from a paper-based quality system to a paperless one.

Orbit Irrigation

Orbit Irrigation (Husqvarna Group) is the world's largest manufacturer of sprinkler heads, smart timers, valves, manifolds, and other accessories for residential, agricultural, and commercial irrigation systems. These complex assemblies contain dozens to hundreds of mechanical and electrical components sourced from suppliers around the globe.

With 1factory, Orbit Irrigation was able to move away from paper and excel to digital inspection planning, data collection, and analysis. Once 1factory was selected, the results were practically immediate.

"The time savings and reporting accuracy just went through the roof with 1factory, and so many of my tasks have been simplified.", Robin Bushman, Quality Manager

Able Tool Corporation

Able Tool Corporation, founded in 1984, specializes in high-mix complex CNC precision components.

"1factory has been a game changer for us.", Paul Hayes, President

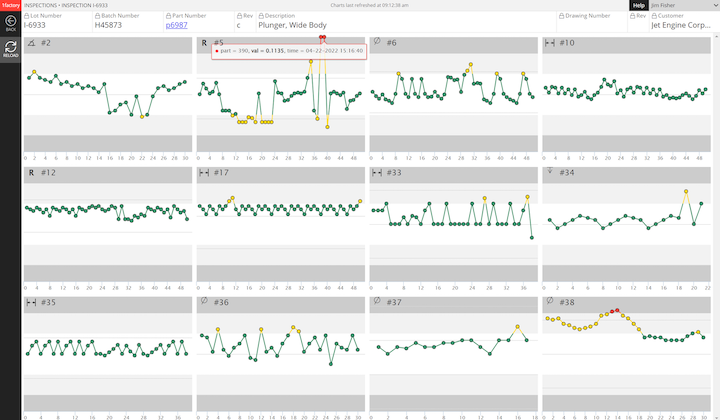

The 1factory platform was introduced to Able Tool Corporation by their customer, a Major Aerospace OEM. Using 1factory's Supplier Collaboration Portal, Able Tool was able to create and share plans, FAIs, and ongoing production inspection data directly with their OEM customer.

Within the first week, Able Tool successfully delivered 54 FAIs to their customer and realized significant productivity gains. By the end of the first month, Able Tool had delivered over 200 FAIs and decided to adopt 1factory as their internal Quality Control software, transforming their manufacturing operations.

W.H. Bagshaw

W.H. Bagshaw, established in 1870, manufactures CNC precision components for the medical, aerospace, defense, agriculture and other industries

By leveraging 1factory, W.H. Bagshaw has realized significant savings in time, resources, and effort. For instance, conducting capability studies for a customer has led to the adoption of centerless ground material, resulting in reduced setup times and decreased scrap rates. These efficiencies directly contribute to cost savings and improved overall productivity.

They now benefit from cleaner inspection and First Article Inspection (FAI) reports, enhanced visualization of priority jobs for management, and improved reporting capabilities for customer requests.

The ability to provide data-driven charts demonstrating their manufacturing capability has strengthened their relationships with clients.

J&L Manufacturing

J&L Manufacturing provides a range of metal forming services (metal cutting, bending, stamping, welding and machining) to the automotive, hospital and other industries.

J&L did not have the manpower to support heavy PPAP documentation requirements and would turn away orders that required PPAPs. Then they found 1factory. And with 1factory, J&L was able to drop PPAP creation time from a week to just two hours.

With 1factory, J&L completed 168 PPAPs in the first 7 months of the year, and averages 5 PPAPs a week. More importantly nearly all PPAPs were delivered 100% accurate and complete in the first pass. They can now accept all the orders coming their way, and can grow their business.

Savage Arms Canada

Savage Arms Canada, located in Lakefield, Ontario, is a leading firearms manufacturer known for producing high-quality rifles, shotguns, and accessories.

"1factory has streamlined our PPAP process by automating the administrative tasks involved with documentation, speeding up submissions and approvals."

"With its automated data validation and centralized document management, 1factory ensures that all our information is accurate and up to date. The platform is designed to handle large volumes of data and complex processes, making it suitable for manufacturers of all sizes.", Arron McChesney, Quality Manager.