Powerful, Easy-to-Use, Lightning-Fast

Incoming Quality Control Software (IQC Software)

Simplify and speed-up incoming inspections. Verify critical component quality, and use intelligent data-driven lot-switching to focus attention on the highest risk parts and suppliers, while eliminating unnecessary inspections.

Dramatically reduce inspection costs. Free-up IQC capacity. Reduce the risk of defective parts entering production.

VERIFY INCOMING COMPONENT QUALITY. REDUCE DEFECT RISK AND INSPECTION COST.

EFFICIENCY & COST SAVINGS

“This software is amazing what it can do!! The efficiency and cost-effectiveness alone was a big win for us. This Receiving Inspection Software provides less paper work, fewer errors, more quality, monitoring capabilities, spec. requirements, inspection plans, supplier dashboards, all of this and so much more. And did I mention the money it saved in labor...outstanding!!! Altogether a winning situation.”

M. Carrasco, IQC Manager, Viavi Systems

IQC FEATURES

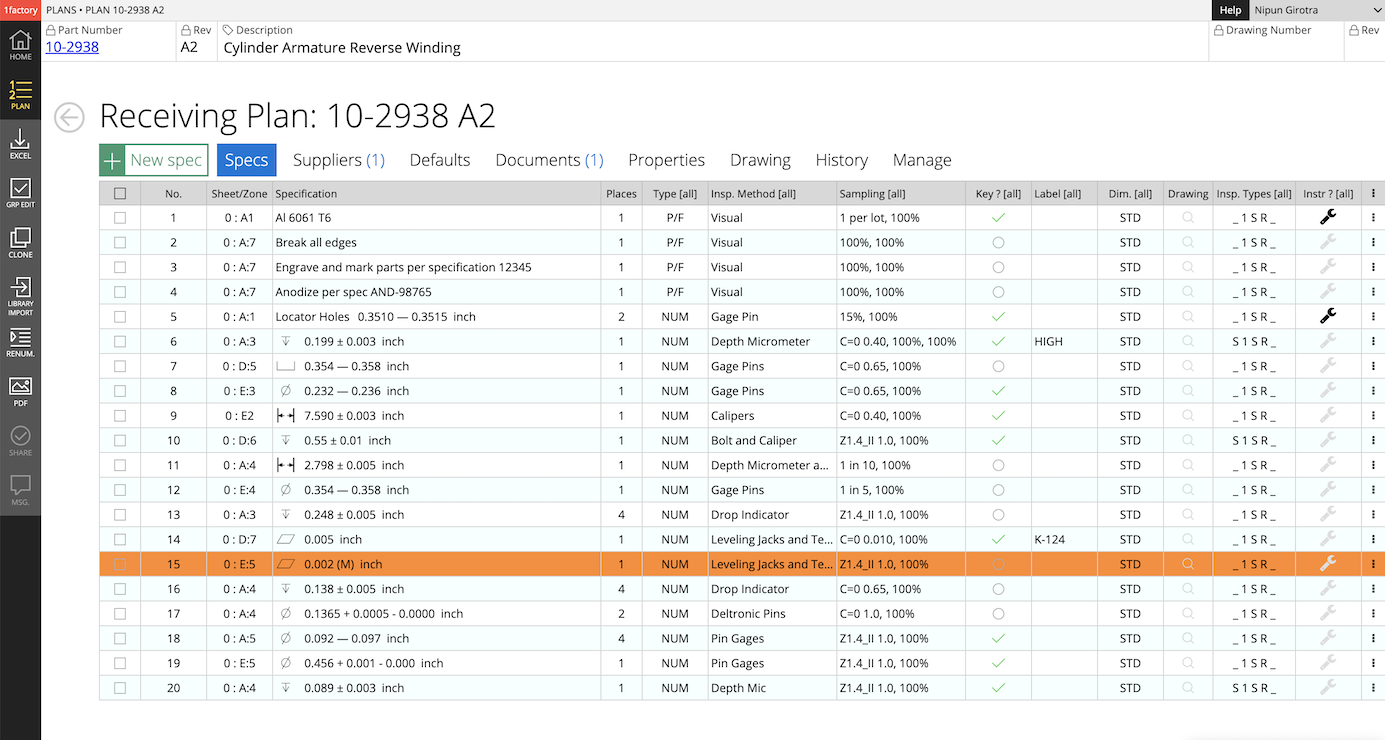

1Incoming Inspection Plans

Balloon drawings or import spec sheets to create Incoming Inspection Plans. Define inspection methods, work instructions, and sampling rules for each feature. List approved suppliers. Track changes with history and version control.

2Incoming First Article

Create First Article records and verify supplier first articles in minutes with digital IQC data collection from hand-held tools, Vision Systems, and CMMs.

3Sample Size Calculation

Set-up sampling requirements based on C=0, ANSI Z1.4, MIL-STD, customer-provided, and custom sampling plans. Auto-calculate sample size for each feature based on lot size and sampling plan. Ensure all required measurements are recorded before inspections are closed.

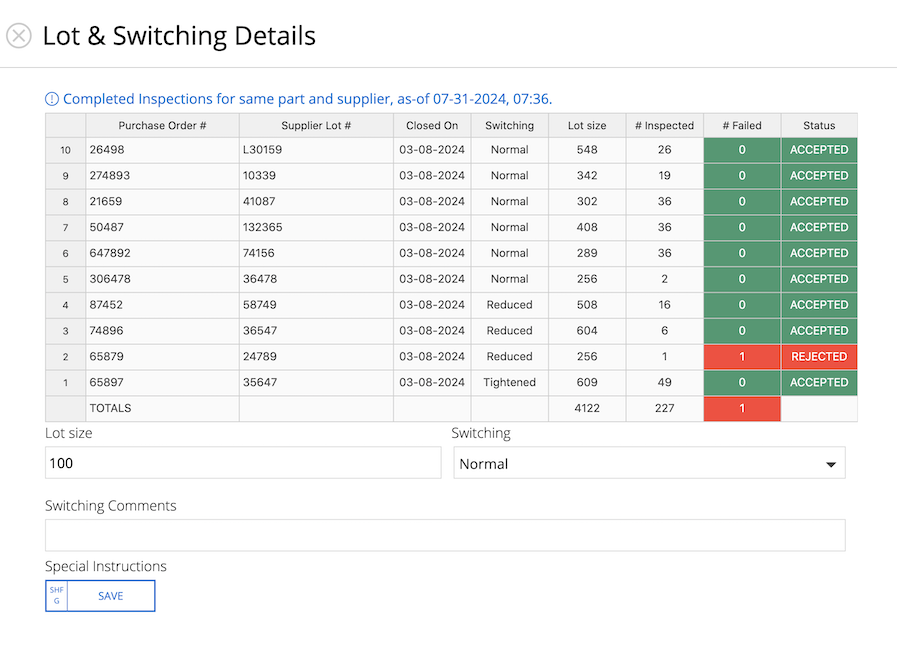

4Lot Switching

Use built-in lot switching rules (Normal, Reduced, Tightened) and decision-support data, to tighten or reduce inspection requirements based on historical part and supplier performance. Increase sampling for high-risk parts and suppliers, and reduce sampling for low-risk parts and suppliers.

5Record Measurements & Certs

Inspect incoming components. Capture visual and dimensional checks, and associate raw material and outside processing certificates of conformance.

6Digital IQC Data Capture

Record measurement data from digital gages with a single click. Auto-import millions of measurements from Vision systems and CMMs in seconds. Eliminate unnecessary data entry, errors, and paperwork.

7Supplier Dashboard & Scorecard

Monitor ongoing Quality and On-Time-Delivery performance for each supplier. Compare part-quality performance across suppliers. Generate supplier scorecards with a single click.

8NCRs and SCARS

Generate a non-conformance report from within an inspection with a single click. Create and assign Supplier Corrective Action Reports (SCARs). Review supplier responses and track SCARs to completion.

CASE STUDIES

Read Highlights & Transcript

Highlights: Digital IQC & Supplier Quality Transformation

- Automated Incoming Inspection: Zipline replaced fragmented, "dusty" control plans with 1factory's IQC software, enabling real-time verification of critical components.

- Global Supplier Collaboration: Standardized First Article Inspection (FAI) and ongoing inspection data submissions across a global supply chain.

- Reliability: Ensuring 100% quality for life-saving drones by focusing incoming quality control resources on high-risk parts.

Transcript Excerpt: "1factory is the best SaaS software Zipline uses. We are solving the problem of stale control plans and lack of supplier monitoring of quality data."

Zipline - Global Supplier Quality

Zipline designs, manufactures and operates the world's largest autonomous delivery system. High-quality parts are critical to reliable flight and delivery of life-saving supplies.

Zipline deployed the 1factory system across its supply chain to ensure high-quality parts from global suppliers. Today suppliers create Control Plans and First Articles and submit them for review and approval via 1factory.

"1factory is the best SaaS software Zipline uses" - Keenan W. CTO.

Watch a 7-minute video to hear first-hand from the Zipline team about the power of 1factory, its ease-of-use, and its impact on cost of quality.

Orbit Irrigation (Husqvarna) - Irrigation Products

Orbit Irrigation is the world's largest manufacturer of sprinkler heads, smart timers, and valves. These complex assemblies contain dozens to hundreds of mechanical and electrical components sourced from suppliers around the globe.

With 1factory, Orbit Irrigation was able to move away from paper and excel to digital incoming inspection planning, data collection, and analysis. Once 1factory was selected, the results were practically immediate.

"The time savings and reporting accuracy just went through the roof with 1factory." says Robin Bushman, Quality Manager.

EASY TO USE. LIGHTNING FAST. SECURE & RELIABLE

INTUITIVE DESIGN & LIGHTNING FAST SPEED

1Factory's intuitive interface and streamlined workflows make training effortless - most teams achieve full deployment in under two hours with zero operational disruption.

Speed is non-negotiable on the shop floor. Every interaction - from data entry to ballooning to search - happens instantaneously. Your manufacturing operations run at full pace, never waiting on software. With 24/7/365 global availability and real-time analytics, 1Factory keeps your quality operations moving at the speed of production.

SECURITY & RELIABILITY

1Factory meets the security standards that matter to regulated manufacturers: ITAR-compliant hosting on AWS GovCloud, full NIST 800-171 compliance, and SOC 2 Type 2 certification. Your quality data stays protected and audit-ready.

Over the past decade, 1Factory has maintained >99.99% uptime - because we understand that your quality system can't afford downtime. Data encryption, daily database snapshots, and redundant file storage ensure your critical quality records are always protected and recoverable.

BENEFITS: INCOMING QUALITY CONTROL SOFTWARE

CHALLENGES IN INCOMING QUALITY CONTROL

Incoming Quality Control (IQC) serves as a critical defense against defective supplier parts entering production. Despite supplier quality agreements and certifications, manufacturers must verify incoming materials against specifications through systematic inspection and testing. This encompasses everything from dimensional measurements and material verification to functional testing and documentation review.

However, traditional IQC alone often proves inadequate - by the time defects are caught at incoming inspection, entire shipments may be affected and production schedules already compromised. Today's manufacturers face mounting pressure on their incoming inspection teams: increasing part complexity, proliferating product variants, and accelerating delivery schedules.

Quality teams struggle to prioritize inspections effectively, often resorting to time-consuming spreadsheets to track requirements and results. Without real-time visibility into supplier quality trends, manufacturers cannot adjust inspection protocols dynamically, leading to either excessive inspection costs or increased risk of defect escapes.

THE 1FACTORY INCOMING QUALITY CONTROL SOFTWARE SOLUTION

1factory transforms incoming inspection from a reactive bottleneck into a proactive quality assurance system. By providing real-time visibility into supplier quality trends, the platform enables manufacturers to address quality issues before they impact production schedules and compromise entire shipments.

1factory's intelligent lot-switching algorithms automatically adjust inspection protocols based on supplier performance data, focusing resources on the highest risk parts and suppliers while reducing unnecessary inspections of proven components. This dynamic approach eliminates the guesswork of prioritizing inspections across increasing part complexity and proliferating product variants.

The platform replaces time-consuming spreadsheets with automated tracking of inspection requirements and results across all suppliers and parts. IQC operators gain instant access to relevant specifications, history, and testing protocols, dramatically speeding up the inspection process while improving accuracy and consistency.

Quality managers gain powerful analytics to optimize inspection protocols continuously, balancing quality assurance with operational efficiency. This data-driven approach ensures critical component quality while unlocking significant productivity gains, enabling IQC teams to handle accelerating delivery schedules without compromising standards.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & INDUSTRIAL

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS