Powerful, Easy-to-Use, Lightning-Fast

FAI Software & Drawing Ballooning Software

Balloon drawings, build Control Plans, and populate FAIs in minutes. Extract notes, dimensions, tolerances, and GD&T. Import CMM data. Record Gage IDs with verified calibration. Generate First Article Inspection (FAI) reports in AS9102 and other formats.

Cut FAI cycle time from days to hours. Eliminate manual errors. Accelerate new product introduction.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & INDUSTRIAL

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS

SPEED-UP DRAWING BALLOONING. SAVE HOURS OF FIRST ARTICLE TIME.

HUGE TIME SAVER

“Recently we had a spike in new business with over 60 parts needing First Articles. With the help of 1factory (first article inspection software) we were able to bubble the drawings, program our CMM to the bubble drawing and directly download the data right onto the First Article form. It was a huge time saver!”

B. Terry, Quality Manager, Kalman Manufacturing

54 FAIs IN THE FIRST WEEK

“1factory has been a game changer for us". Within the first week, Able Tool successfully delivered 54 FAIs to their customer and realized significant productivity gains. By the end of the first month, Able Tool had delivered over 200 FAIs.

P. Hayes, President, Able Tool

PDF DRAWING AUTO-BALLOONING & FAI SOFTWARE FEATURES

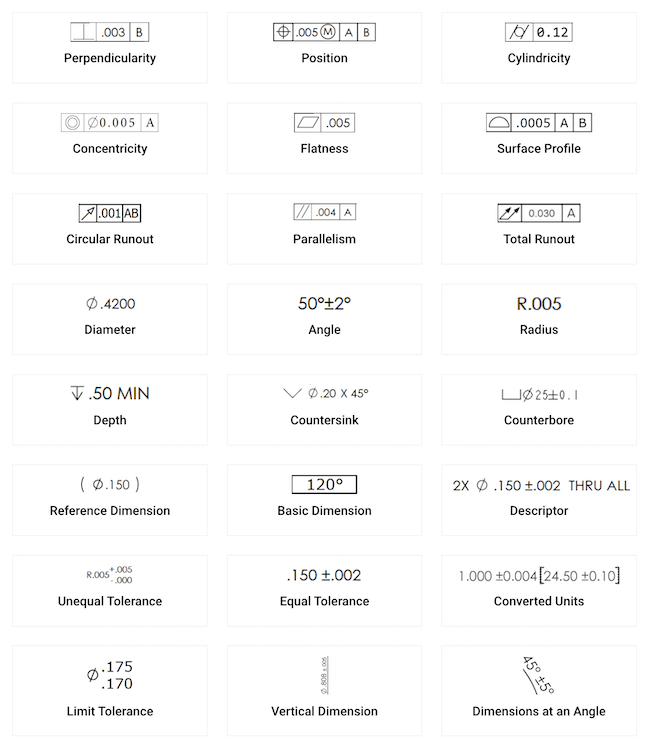

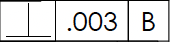

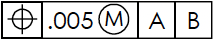

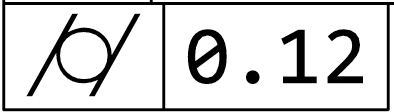

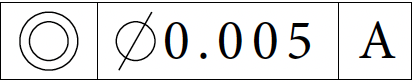

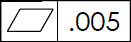

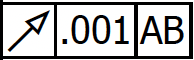

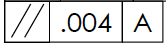

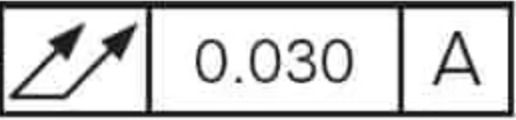

1GD&T (Form) & OCR Recognition

Leverage 1factory's powerful proprietary OCR capabilities to instantly identify and auto-balloon all GD&T features on your engineering drawings. Automatically extract complex feature control frames, including true position, perpendicularity, parallelism, and profile tolerances, into your digital inspection plan.

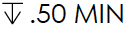

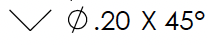

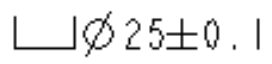

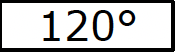

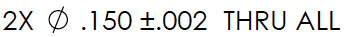

2Dimensions & Features of Size

Accelerate drawing ballooning by instantly auto-ballooning all features of size. Our FAI software captures diameters, radii, angles, counterbores, and depths directly from PDF drawings, eliminating the manual data entry typically required for first article inspection reports.

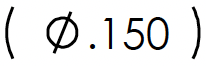

3Basic & Reference Dimensions

Automatically identify and balloon Basic Features required for true position calculations and Reference Features used for auxiliary info. The system distinguishes these from critical characteristics to ensure your AS9102 Form 3 is accurate and compliant.

4Note Extraction & Grouping

Use point-and-click OCR to capture and distinguish general notes from dimensions. Group multiple lines of text into a single requirement or split them into individual characteristics to ensure every drawing note is accounted for in your final FAIR.

5Sheet & Zone Mapping

Improve traceability by automatically capturing the drawing sheet and zone for every ballooned characteristic. For congested drawings, add leader lines with a single click to maintain clarity in your ballooned drawing package.

6Smart Default Tolerances

Automate tolerance population to eliminate manual lookup errors. Our system applies tolerances based on decimal places for US imperial drawings or feature size for metric drawings following ISO 2768 coarse, medium, or fine standards.

7Digital Control Plans & Ops Sheets

1factory is the only system that converts your FAI ballooning work into a production Control Plan. Add Process Drawings or Ops Sheets to build an end-to-end inspection plan that flows seamlessly from first article to production.

8Automated Unit Conversion

Convert dimensions between inches and millimeters with a single click. This allows your shop floor to record data in their preferred units while generating customer reports in the format required by the engineering drawing.

9Drawing Revision Comparison

Protect your process from design changes with automated revision comparison. Instantly detect and highlight nominal or tolerance changes between drawing revisions, allowing you to update your inspection plan in seconds.

10CMM Data Import & Automation

Stop manual transcription and eliminate errors by importing measurement data for hundreds of parameters. Our FAI software supports automated data capture from Zeiss, Mitutoyo, Keyence, and PCDMIS, as well as connected digital gages.

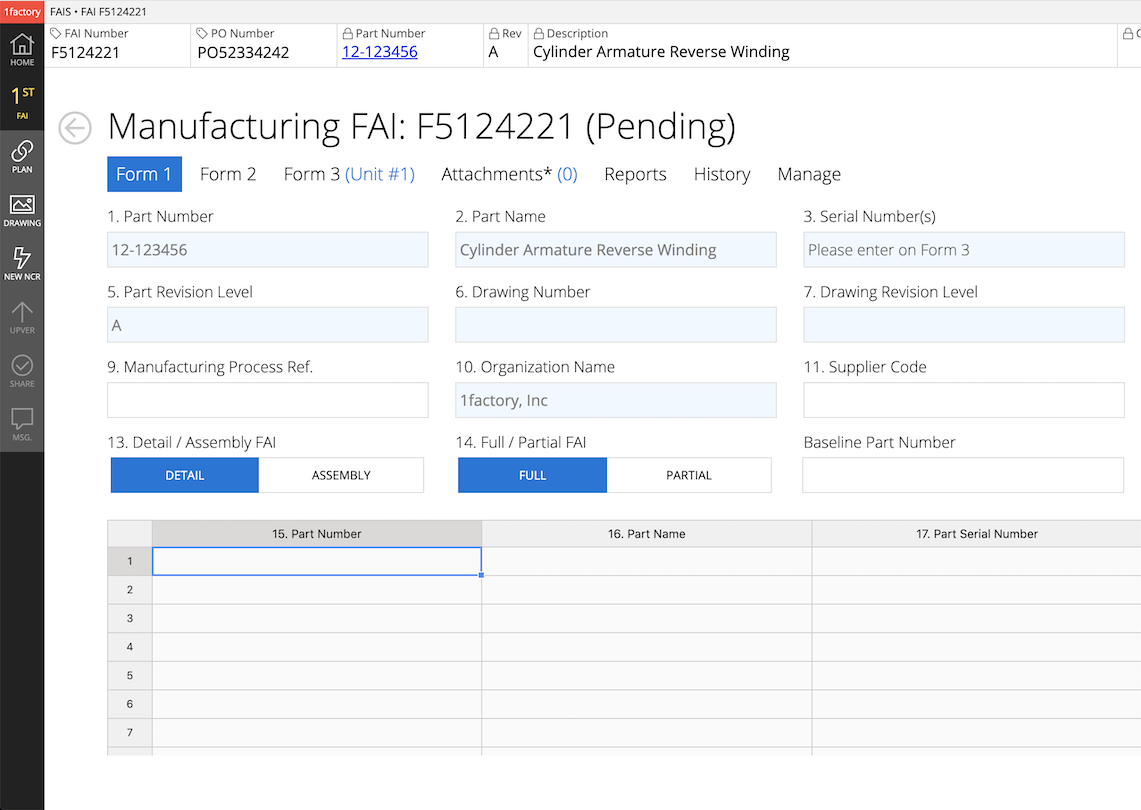

11AS9102 Form 1, 2, & 3 Reports

Generate fully-finished First Article Inspection Reports in standard AS9102 format with one click. Export data seamlessly for upload to Net-Inspect or other customer-specific quality portals.

12Full & Partial FAIR Management

Effortlessly manage Full reports for initial production and Partial FAIRs for engineering changes. 1factory tracks your FAI history so you only have to inspect what changed in subsequent revisions.

13Integrated Assembly FAIRs

Simplify complex documentation by linking Component FAIs to parent Assembly FAIs. This creates an integrated Assembly First Article Inspection Report that ensures full multi-level traceability.

1FACTORY'S POWERFUL OCR AUTOMATICALLY RECOGNIZES ALL FEATURE TYPES

Perpendicularity

Position

Cylindricity

Concentricity

Flatness

Surface Profile

Circular Runout

Parallelism

Total Runout

Diameter

Angle

Radius

Depth

Countersink

Counterbore

Reference

Basic

Descriptor

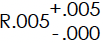

Unequal Tol

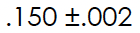

Equal Tol

Converted

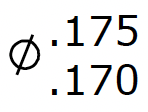

Limit

Vertical

Angled

CASE STUDIES

Read Highlights & Transcript

Highlights: Accelerating Aerospace FAI & AS9102 Success

- Rapid Implementation: Next Intent went live in a single day, contrasted with a competitor's estimated 9-month setup period.

- Instant Productivity: The company had its first inspection plan and FAI software output in the system within 20 minutes.

- AS9102 FAIR Volume: Successfully delivered over 500 First Article Inspection Reports to customers for mission-critical parts.

- Massive Time Savings: Reduced FAIR reporting time from ~60 minutes per form to just a few minutes.

- Eliminating Errors: Eliminated paperwork errors and gained a single point of truth for drawings and measurement data.

Transcript Excerpt:

00:00 - Introduction: CEO Rodney B. introduces Next Intent as a precision manufacturer for aerospace, serving billion-dollar missions where failure is catastrophic.

00:35 - Why 1factory: We were about to order a competitor's product with a 9-month install, but 1factory promised we would be live in one day.

01:15 - "Worked Like the Demo": The software worked exactly as promised. Within 20 minutes, I had bubble-printed a drawing and created a plan and inspection sheet.

01:40 - Data Confidence: Auditing and data entry became significantly easier, reducing common manual errors and providing absolute traceability.

Next Intent - Aerospace, Space, Defense

Next Intent is a world-class precision manufacturer, serving the aerospace and semiconductor industries. The parts they craft are critical to the success of missions where a single failure is catastrophic.

Notable projects include components for Mars rovers and the Giant Magellan Telescope. Next Intent picked 1factory to meet its challenging requirements for quality planning, FAI, and inspections.

"The Software worked just like the demo!" Rodney B. President & CEO.

"The implementation time for a competitor was nine months. With 1factory, they were getting it to work within the first day.".

EASY TO USE. LIGHTNING FAST. SECURE & RELIABLE

INTUITIVE DESIGN & SPEED

1Factory's intuitive interface makes training effortless - most teams achieve full deployment in under two hours with zero operational disruption.

Speed is non-negotiable on the shop floor. Every interaction - from data entry to ballooning - happens instantaneously. Your manufacturing operations run at full pace, never waiting on software.

SECURITY & RELIABILITY

1Factory meets security standards like ITAR-compliant hosting on AWS GovCloud, full NIST 800-171 compliance, and SOC 2 Type 2 certification. Your quality data stays protected and audit-ready.

Over the past decade, 1Factory has maintained >99.99% uptime. Data encryption, daily database snapshots, and redundant file storage ensure your records are always recoverable.

FAQ: FAI & BALLOONING AUTOMATION

What should you consider when selecting First Article Inspection Software?

A First Article Inspection record is much more than just an Excel report. When evaluating a professional-grade platform, ensure it addresses these five critical requirements:

- Drawing Ballooning: Does the software significantly speed up the characteristic identification process?

- Integrated Quality Planning: Can it automatically convert FAI data into a Control Plan for production?

- CMM & Equipment Integration: Does it import data directly from CMMs, optical scanners, and digital gages?

- Document & CoC Management: Can the system store and link material certs (CoCs) and sub-component FAIs?

- Search & Data Retention: Can you retrieve records by part or gage ID years later? (Crucial for multi-decade Aerospace and Medical Device record retention contracts).

How does 1factory bridge the gap between FAI and full-scale production?

Point Solutions Problem: Most FAI software acts as a standalone "point solution" - you balloon a drawing to generate a report, but that data remains isolated. To move to production, you are forced to manually re-enter those same characteristics into a separate system for shop-floor inspection.

Integrated Workflow: 1factory eliminates this data transfer problem. Our platform links ballooned drawings directly to control plans, which then drive your FAIs, PPAPs, daily inspections, and SPC. This ensures the work done during the First Article stage supports the entire manufacturing lifecycle without manual re-entry.

Why is 1factory's auto-ballooning faster than the competition?

Proprietary OCR Engine: While competitors rely on generic, slow OCR or bulky AI models, 1factory uses a proprietary recognition engine optimized specifically for engineering symbols and GD&T frames.

This deterministic approach delivers a lightning-fast experience where ballooning happens instantaneously. Because our engine is purpose-built for manufacturing, it identifies dimensions and notes without the lag or "guessing" common in general-purpose tools.

How does 1factory compare to legacy FAI tools and "Point Solutions"?

Cloud-Native Collaboration: Unlike desktop-based tools that trap data on a single PC, 1factory is a secure, cloud-native platform. This allows for real-time collaboration between inspectors, engineers, and even suppliers.

Immediate Go-Live: While legacy platforms project 9-month implementation cycles, 1factory customers frequently go live in one day. Teams often see their first inspection plan and FAI output in under an hour.

What is the typical Return on Investment (ROI)?

Increased Throughput: By reducing FAI and PPAP creation time by up to 65%, quality departments can handle a higher volume of new product introductions. Customers have reported delivering as many as 54 FAIs in a single week, allowing them to take on new work and grow their business.