Powerful, Easy-to-Use, Lightning-Fast

APQP and PPAP Management Software

Speed-up PPAP creation including PFMEAs, Control Plans, Process Capability, Gage R&Rs, and more. Manage internal PPAPs, supplier PPAPs, delta PPAPs, and assembly PPAPs.

Cut PPAP cycle time from days to hours. Save hundreds of man-hours each year. Accelerate new product introduction.

SIMPLIFY PPAP CREATION AND MANAGEMENT. SPEED UP NEW PRODUCT INTRODUCTION.

SPEED UP PPAP CREATION

“Before 1factory, one PPAP would take me at least a week from start to finish.

Now, with 1factory, it takes me an hour, maybe two, from start to finish. I'm at 168 PPAPs for the year already (with a 1-person team).

There are also fewer mistakes in them. One of our customers forwards our PPAPs along to their customer, and they can't believe how fast they get accepted." Read the Case Study

Christy W., Quality Manager, J&L Manufacturing

PPAP & APQP FEATURES

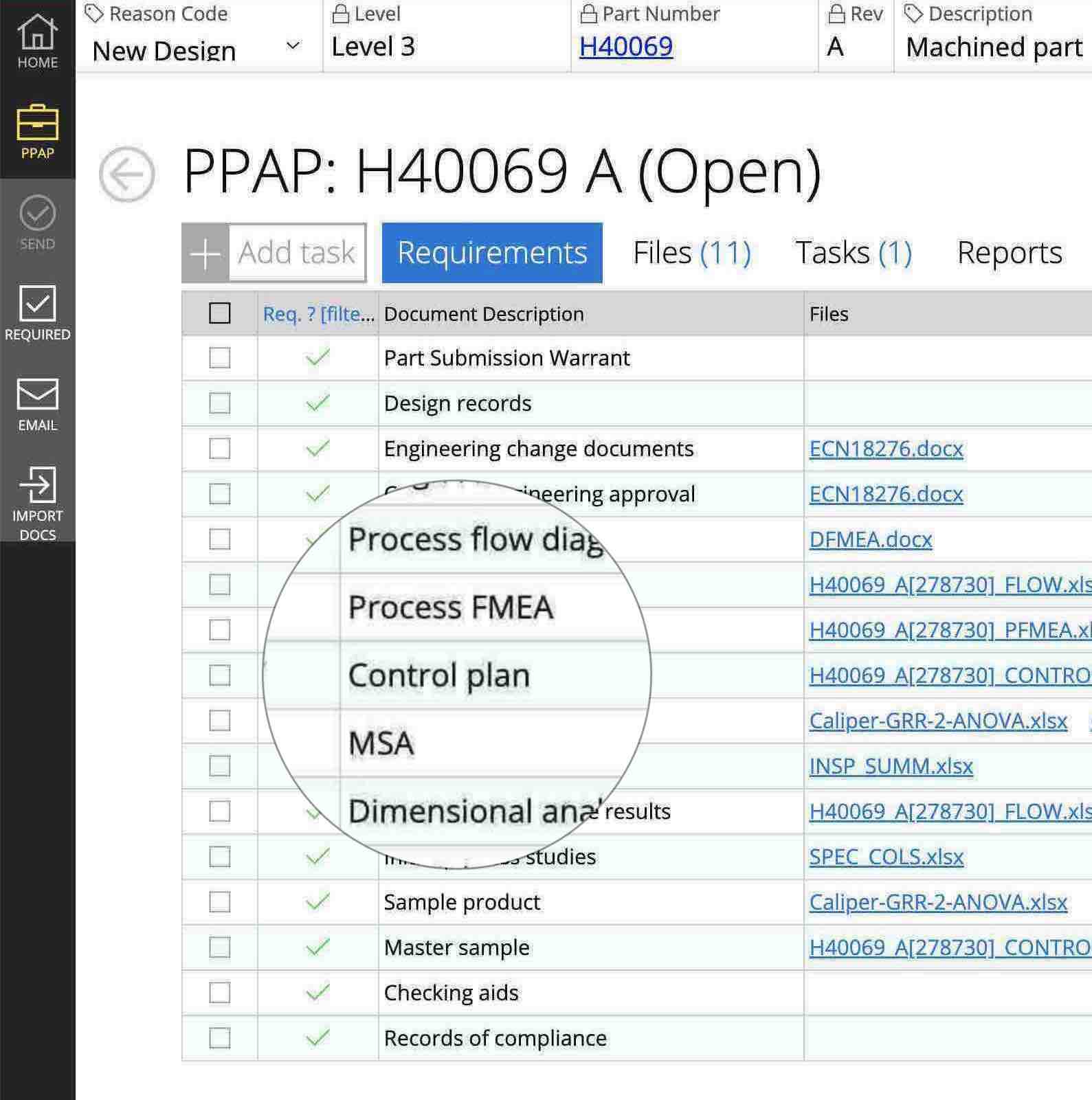

1 Internal (Customer) PPAPs

Author, collect and manage the various PPAP elements - Process Flow, Control Plan, PFMEA, Measurement Data, Certs, Gage R&R etc. - from various departments (engineering, manufacturing, quality control etc.) into a PPAP package for delivery to a customer.

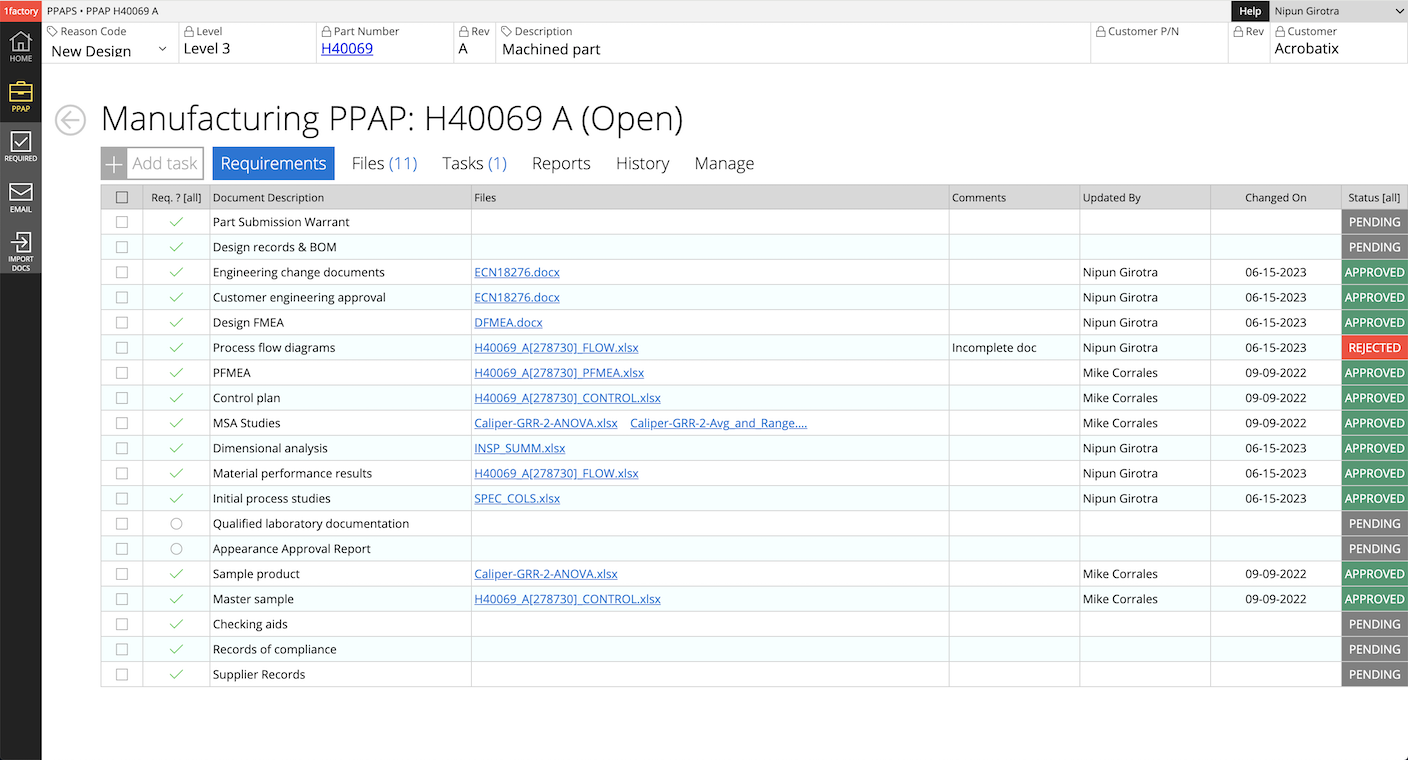

2 Supplier PPAPs

Assign PPAPs to suppliers with a clear list of requirements and due dates. Define levels and required documents by level. Receive PPAPs from suppliers within 1factory. Provide real-time feedback with powerful Messaging capability. Review and approve individual requirements and notify suppliers of status change.

3 PPAP Levels

Easily define and manage custom PPAP levels by product type and/or customer. Define custom lists of required and optional documents by PPAP level.

4 PPAP Project Management

Collaborate within your factory and across your supply chain with powerful Messaging and Tasks capabilities. Review and approve individual requirements and the entire PPAP package.

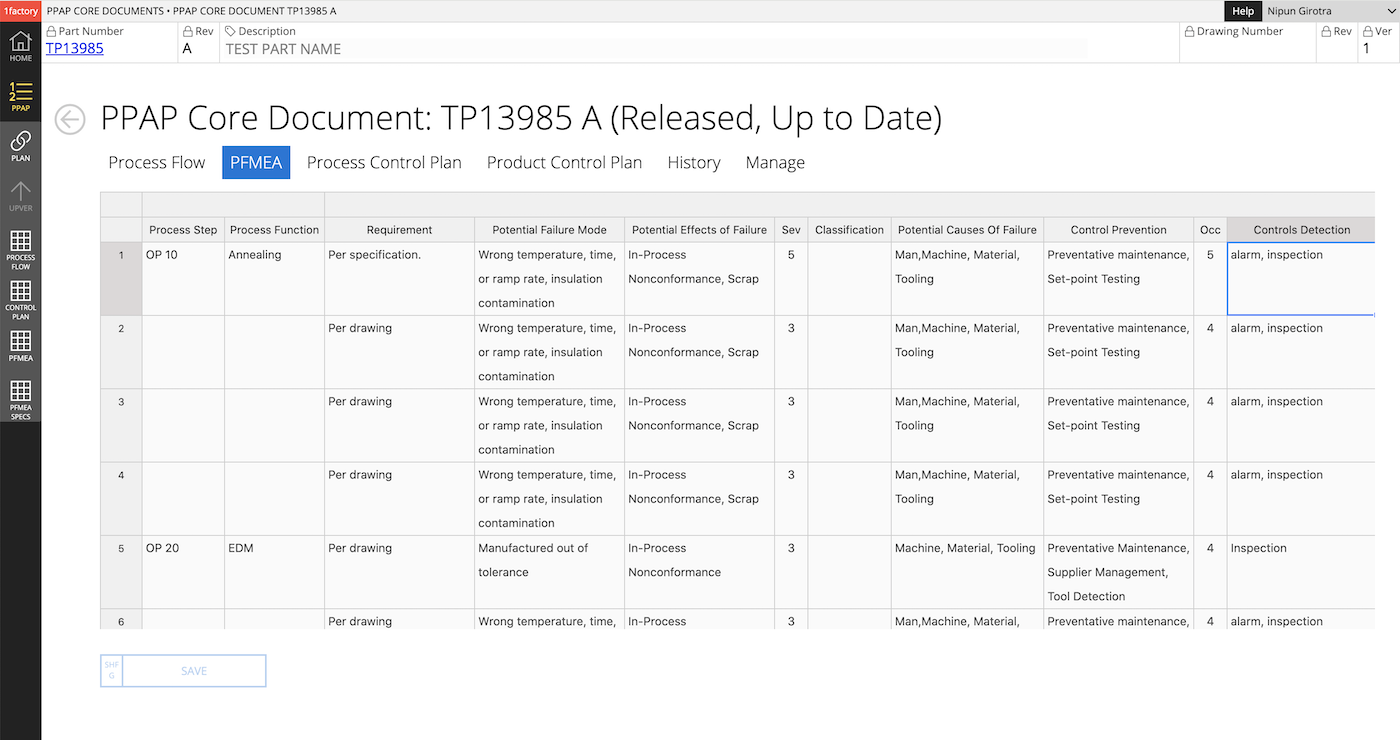

5 Master (Foundational) PFMEA

Build a library of failure modes by Manufacturing Process (e.g. Mill-Turn, Grinding, Plating, Deburring etc.). Automatically populate a part-number-specific PFMEA with Failure Modes, Effects, Severity, Causes, etc. from the Library and save hours of time. Ensure changes made to the Master (Foundational) PPAP are synched with each Part's PFMEA.

6 Process Flow Diagram

Build a library of failure modes by Manufacturing Process (e.g. Mill-Turn, Grinding, Plating, Deburring etc.). Automatically populate a part-number-specific PFMEA with Failure Modes, Effects, Severity, Causes, etc. from the Library and save hours of time.

7 PFMEA

Build and maintain part-number-specific PFMEAs with version control. Identify product-feature and process failure modes. Output PFMEA reports in AIAG/APQP, or AS13000 formats with a single-click.

8 Control Plan

Instantly analyze data with built-in lightning-fast reports and dashboards without expensive 3rd-party BI tools. Analyze data across work-orders. Drill-down to Part, Feature, Vendor, Inspector, Machine etc.

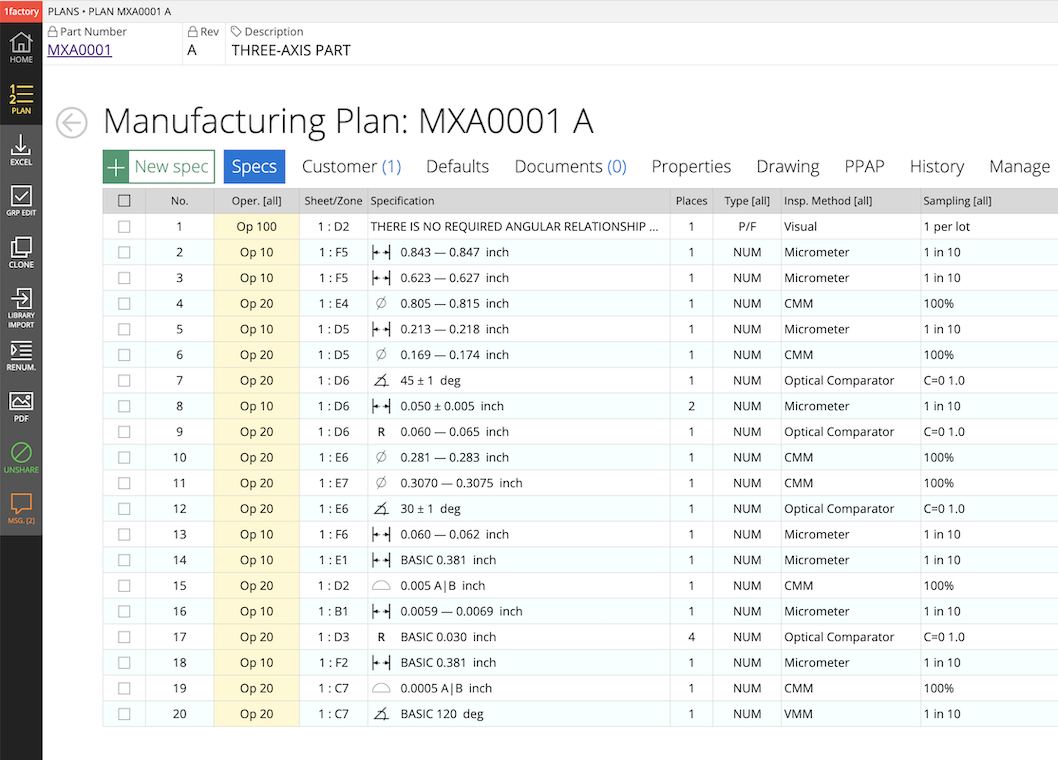

9 Dimensional Results

Collect factory-floor measurements from hand-held tools and CMMs, and create initial sample reports for PPAPs.

10 Measurement Systems Analysis

Perform Variable Gage R&R with configurable number of operators, parts and trials. Enjoy automated calculations and output reports with either the ANOVA or Range methods.

11 Process Capability & SPC

Automatically calculate Process Capability (Cp, Cpk) and Process Performance (Pp, Ppk) metrics for each feature. Use individuals charts and Western Electric detection rules to demonstrate control over manufacturing processes. Output capability reports for PPAP packages.

12 Delta & Revalidation PPAPs

Create and manage PPAPs for new products. Create and manage delta PPAPs for changes to engineering designs, manufacturing processes, suppliers etc. Automatically create periodic revalidation PPAPs.

CASE STUDIES

J&L Manufacturing - Automotive, Hospital Equipment

J&L Manufacturing provides a range of metal forming services (metal cutting, bending, stamping, welding and machining) to the automotive, hospital and other industries.

J&L did not have the manpower to support heavy PPAP documentation requirements and would turn away orders that required PPAPs. Then they found 1factory. And with 1factory, J&L was able to drop PPAP creation time from a week to just two hours.

J&L completed 168 PPAPs in the first 7 months of the year, and averages 5 PPAPs a week. More importantly nearly all PPAPs were delivered 100% accurate and complete in the first pass. They can now accept all the orders coming their way, and can grow their business.

EASY TO USE. LIGHTNING FAST. SECURE & RELIABLE

INTUITIVE DESIGN & LIGHTNING FAST SPEED

1Factory's intuitive interface and streamlined workflows make training effortless - most teams achieve full deployment in under two hours with zero operational disruption.

Speed is non-negotiable on the shop floor. Every interaction - from data entry to ballooning to search - happens instantaneously. Your manufacturing operations run at full pace, never waiting on software. With 24/7/365 global availability and real-time analytics, 1Factory keeps your quality operations moving at the speed of production.

SECURITY & RELIABILITY

1Factory meets the security standards that matter to regulated manufacturers: ITAR-compliant hosting on AWS GovCloud, full NIST 800-171 compliance, and SOC 2 Type 2 certification. Your quality data stays protected and audit-ready.

Over the past decade, 1Factory has maintained >99.99% uptime - because we understand that your quality system can't afford downtime. Data encryption, daily database snapshots, and redundant file storage ensure your critical quality records are always protected and recoverable.

BENEFITS: PPAP MANAGEMENT SOFTWARE

PPAP (PRODUCTION PART APPROVAL PROCESS) CHALLENGES

The Production Part Approval Process (PPAP) - a critical step in the new-product introduction (NPI) process - validates a manufacturer's capability to consistently produce high-quality parts at the rate required by the customer.

This comprehensive evaluation examines everything from engineering documentation and raw materials to special processing steps and functional testing, enabling suppliers to evaluate manufacturability and establish robust production processes while allowing buyers to validate all manufacturing steps and verify capacity.

However, today's manufacturers face increasingly complex PPAP requirements from their customers (internal PPAPs or customer PPAPs) and must then flow-down and manage these requirements across their supply-base.

Without efficient systems, teams waste countless hours manually creating PFMEAs and Control Plans, tracking submissions, and chasing approvals - turning this crucial new product introduction step into a major bottleneck that delays production launches by weeks or months. Only after successful PPAP completion is a part considered ready for volume production, making these delays particularly costly.

1FACTORY PPAP MANAGEMENT SOLUTION

1factory transforms PPAP management by automating the entire process for both internal and supplier submissions. The platform's Process Library accelerates PPAP creation by automatically assembling the Core Docs - Process FLows, PFMEAs and Control Plans - enabling quality teams to create, review, and approve PPAPs in hours instead of days while maintaining consistency and revision control.

1factory provides real-time visibility into supplier PPAP submission status and automates the validation of submissions versus requirements, eliminating the manual tracking and chasing that traditionally consumes valuable team resources.

The comprehensive documentation review process is streamlined through automated workflows that handle engineering drawings, process flows, control plans, and test results efficiently.

The result is a dramatic reduction in PPAP creation and approval time, transforming a traditional bottleneck into a competitive advantage for suppliers and speeding up the NPI process for buyers. This enables faster production launches and ensures parts are ready for volume production without the weeks or months of delays that plague traditional PPAP processes.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & INDUSTRIAL

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS