Powerful, Easy-to-Use, Lightning-Fast

Auto-Ballooning & First Article Inspection Software

Balloon drawings and build Control Plans in minutes. Extract notes, dimensions, tolerances, and GD&T. Import CMM data. Generate First Article Inspection (FAI) reports in industry standard formats, including AS9102.

Cut FAI cycle time from days to hours. Eliminate manual errors. Accelerate new product introduction.

SPEED-UP DRAWING BALLOONING. SAVE HOURS OF FIRST ARTICLE TIME.

HUGE TIME SAVER

“Recently we had a spike in new business with over 60 parts needing First Articles. With the help of 1factory (first article inspection software) we were able to bubble the drawings, program our CMM to the bubble drawing and directly download the data right onto the First Article form. We were able to complete this task of First Articles meeting all deadlines and shipping dates. It was a huge time saver and it made our Quality department shine!”

B. Terry, Quality Manager, Kalman Manufacturing

PDF DRAWING AUTO-BALLOONING & FAI SOFTWARE FEATURES

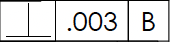

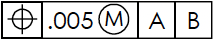

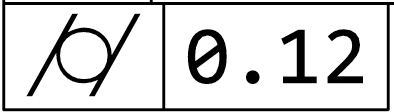

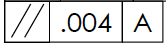

1GD&T (Form)

Instantly identify and auto-balloon all GD&T features on your drawings including true position, perpendicularity, cylindricilty, straightness, angularity, parallelism, flatness, surface profile, runout and more.

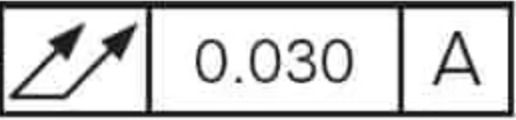

2Dimensions (Size)

Instantly identify and auto-balloon all features of size (i.e. dimensions) including linear-dimension, diameter, radius, angle, chamfer, counterbore, countersink, and more.

3Basic & Reference

Instantly identify and (optionally) balloon Basic Features (needed for true position calculations), and & Reference Features (useful for calculations).

4Notes

Instantly identify and distinguish notes (highlighted in yellow by 1factory) from GD&T and Dimensions (highlighted in blue by 1factory). Point-and-click to capture notes. Group multiple lines into a single note, or break notes into multiple requirements.

5Sheet & Zone, Leader Lines

Automatically capture the exact location - sheet & zone - for every balloon. Add leader lines with just a single click to clearly identify features in congested drawings.

6Default Tolerances

Automatically populate tolerances based on the number of decimal places for US drawings, or based on the size of the feature for mm (ISO 2768) drawings. Easily set up custom tolerance tables, or use the pre-loaded ISO coarse, medium, and fine tolerance tables.

7Ops Sheets or Process Drawings

Add Ops Sheets - Manufacturing Process Drawings - to your ballooned drawing package. Auto-balloon customer drawings and each op-sheet to build a complete end-to-end control plan in minutes.

8Convert Units (inch to mm, and mm to inch)

Convert dimensions from inches to mm or vice versa with a single click. Capture measurements in your shop's preferred unit of measure and convert back to your customer's units for reporting with a single-click.

9Compare Drawing Revisions

Instantly detect and highlight all changes made between drawing revisions. Detect changes such as added, deleted, or modified characteristics, including updated nominals and tolerances, as well as inserted or deleted notes.

10Import CMM & Vision System Data

Capture data from digital gages (micrometers, calipers, height-gages) with a single click. Import measurement data for hundreds of parameters from a wide variety of CMMs - Zeiss, Mitutoyo, PCDMIS, Renishaw, Microvu, Keyence and more - in seconds. Eliminate data-entry-errors.

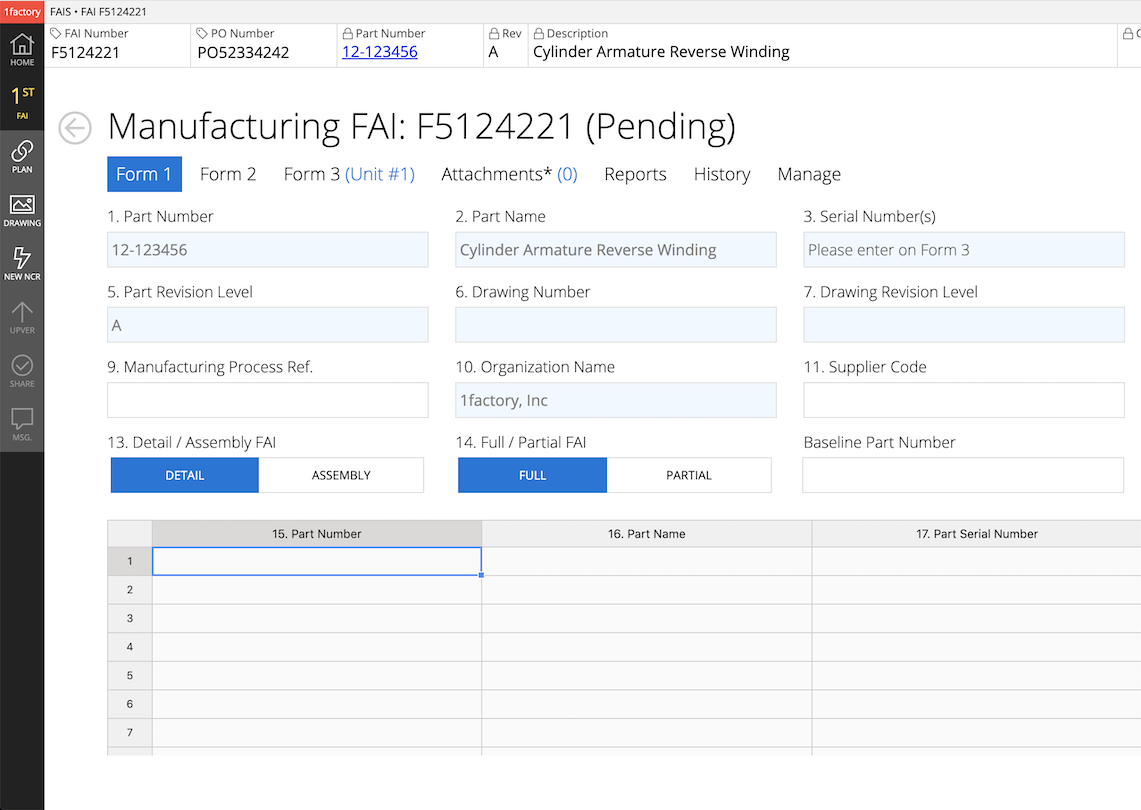

11Create FAI, AS9102 Reports

Output a fully-finished First Article Inspection Report in standard or AS9102 format. Output FAIs for easy upload to Net Inspect or other supplier portals.

12Partial or Full FAIRs

Create Full First Article Inspection Reports for initial production runs, and partial FAIRs for subsequent drawing revisions.

13Assembly FAIRs

Link Component and Assembly FAIRs to create an Assembly First Article Inspection Report.

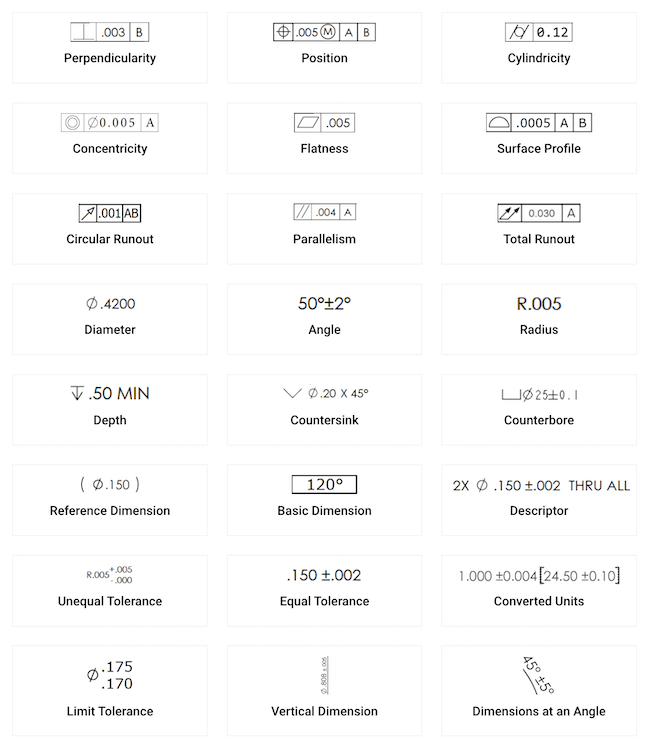

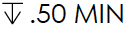

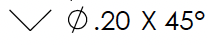

EXAMPLES OF DRAWING FEATURES RECOGNIZED BY 1FACTORY'S POWERFUL OCR

Perpendicularity

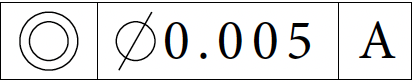

Position

Cylindricity

Concentricity

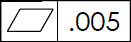

Flatness

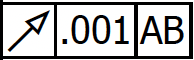

Surface Profile

Circular Runout

Parallelism

Total Runout

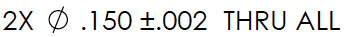

Diameter

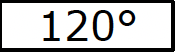

Angle

Radius

Depth

Countersink

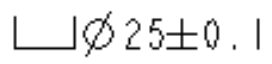

Counterbore

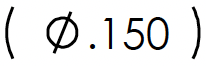

Reference Dimension

Basic Dimension

Descriptor

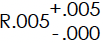

Unequal Tolerance

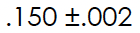

Equal Tolerance

Converted Units

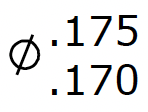

Limit Tolerance

Vertical Dimension

Dimensions at an Angle

CASE STUDIES

Next Intent - Aerospace, Space, Defense

Next Intent is a world-class precision manufacturer, serving the space, defense, aerospace and semiconductor industries. The parts they craft are critical to the success of billion-dollar, multi-decade missions — where a single failure isn't just costly, it's catastrophic.

Notable projects include components for THREE Mars missions, and the revolutionary Red Camera Assembly for the Giant Magellan Telescope and more.

Next Intent picked 1factory to meet its challenging quality requirements. With 1factory, Next intent has unified quality planning, inspections, gage managements, and quality records into one seamless ecosystem, automating paperwork, eliminating errors, and helping deliver the highest quality parts to customers.

"The Software worked just like the demo!" Rodney B. President & CEO.

"We were going to go with another company's software. The implementation time was nine months. That was too long. With 1factory, they were getting it to work within the first day. Within twenty minutes, I had bubble-printed the plans and inspection sheets".

EASY TO USE. LIGHTNING FAST.

INTUITIVE DESIGN

1factory is designed for the front-line of quality control with design inputs and ideas from our users. 1factory's intuitive navigation and best-in-class screen-designs make training a breeze. Training and full-deployment takes under two hours with no disruption to operations.

LIGHTNING FAST SPEED

1factory is engineered to be lightning-fast. We serve customers all over the world 24 hours a day, 7 seven days a week, 365 days a year. Our customers in United States, Mexico, Canada, Israel, China, South Africa, Denmark, UK, India, Malaysia, Taiwan all enjoy lightning-fast data collection and powerful real-time analytics.

SECURE AND RELIABLE

SECURITY

1factory is hosted on AWS GovCloud. The AWS GovCloud service is an isolated Amazon region designed to host sensitive data and regulated workloads, including International Traffic in Arms Regulations (ITAR) data.

All customer data transfer from client to server is encrypted over standard HTTPS/TLS 1.2, using a certificate with 2048-bit RSA public key / SHA-256 with RSA encryption. All customer data is encrypted at rest. Data (e.g. Part Numbers, Measurements etc.) are stored in an encrypted Amazon RDS instance. Drawings, Raw Material Certificates etc. are stored on encrypted Elastic Block Storage (EBS) volumes. Drawings and other documents may be additionally encrypted with individual encryption keys.

1factory complies with all NIST-800-171 requirements. 1factory also maintains a SOC2 Type 2 certification, and a copy is available upon request.

RELIABILITY

1factory has been engineered to be highly reliable, scalable and available. Over 200 million parts have been inspected with 1factory by customers in 33 countries.

1factory has delivered an uptime of >99.99% over the last 8 years. We use a third-party service to monitor system uptime, and our customers can view our uptime and availability metrics in real time.

1factory backs-up database with a daily snapshot. Files are stored on redundant hard-drives and backed up via daily snapshots.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & DEFENSE

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS