Powerful, Easy-to-Use, Lightning-Fast

Auto-Ballooning & FAI Software.

Balloon drawings, extract notes, dimensions, GD&T, sheet and zone and create a control plan with just a few clicks. Import CMM data and generate First Article Inspection (FAI) reports in minutes. Output FAI report in standard, AS9102, and Net Inspect import formats.

SPEED-UP DRAWING BALLOONING. SAVE HOURS OF FIRST ARTICLE PREPARATION TIME.

HUGE TIME SAVER

“Recently we had a spike in new business with over 60 parts needing First Articles. With the help of 1factory (first article inspection software) we were able to bubble the drawings, program our CMM to the bubble drawing and directly download the data right onto the First Article form. We were able to complete this task of First Articles meeting all deadlines and shipping dates. It was a huge time saver and it made our Quality department shine!”

B. Terry, Quality Manager, Kalman Manufacturing

PDF DRAWING READING CAPABILITIES

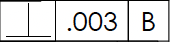

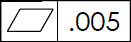

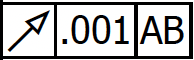

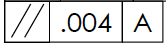

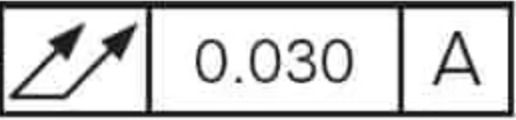

Perpendicularity

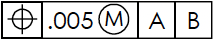

Position

Cylindricity

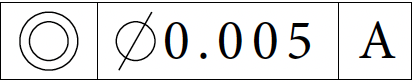

Concentricity

Flatness

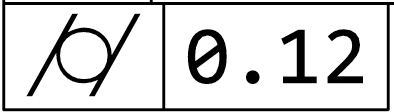

Surface Profile

Circular Runout

Parallelism

Total Runout

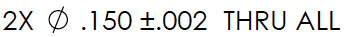

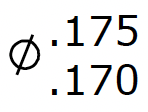

Diameter

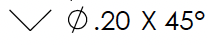

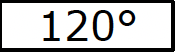

Angle

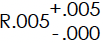

Radius

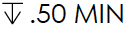

Depth

Countersink

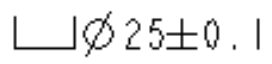

Counterbore

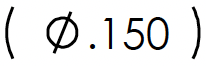

Reference Dimension

Basic Dimension

Descriptor

Unequal Tolerance

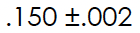

Equal Tolerance

Converted Units

Limit Tolerance

Vertical Dimension

Dimensions at an Angle

DRAWING READING & REVISION COMPARISON FEATURES

POWERFUL IMAGE PROCESSING

1factory's powerful drawing reading algorithm automatically identifies Notes, threads, surface finish, GD&T (position, parallelism, angularity, perpendicularity, surface profile etc.), and features of size (linear dimensions, diameters, radii etc.).

LIGHTNING-FAST AUTO-BALLOONING

The user can then choose to auto-balloon the whole drawing, or point-and-click to manually balloon only the critical dimensions. Both automated and point-and-click ballooning processes extract the characteristic, nominal, tolerances, sheet & zone to the QC Plan.

DRAWING REVISION COMPARISON

In addition to the powerful auto-detection and auto-ballooning capabilities, 1factory also provides powerful drawing revision comparison capability. Customers can instantly find all the changes made between two versions of a drawing by simply loading in the new version of the drawing. 1factory detects the following changes:

- Added Characteristics

- Deleted Characteristics

- Modified Characteristics

- Modified Nominals and Tolerances

- Inserted Notes

- Deleted Notes

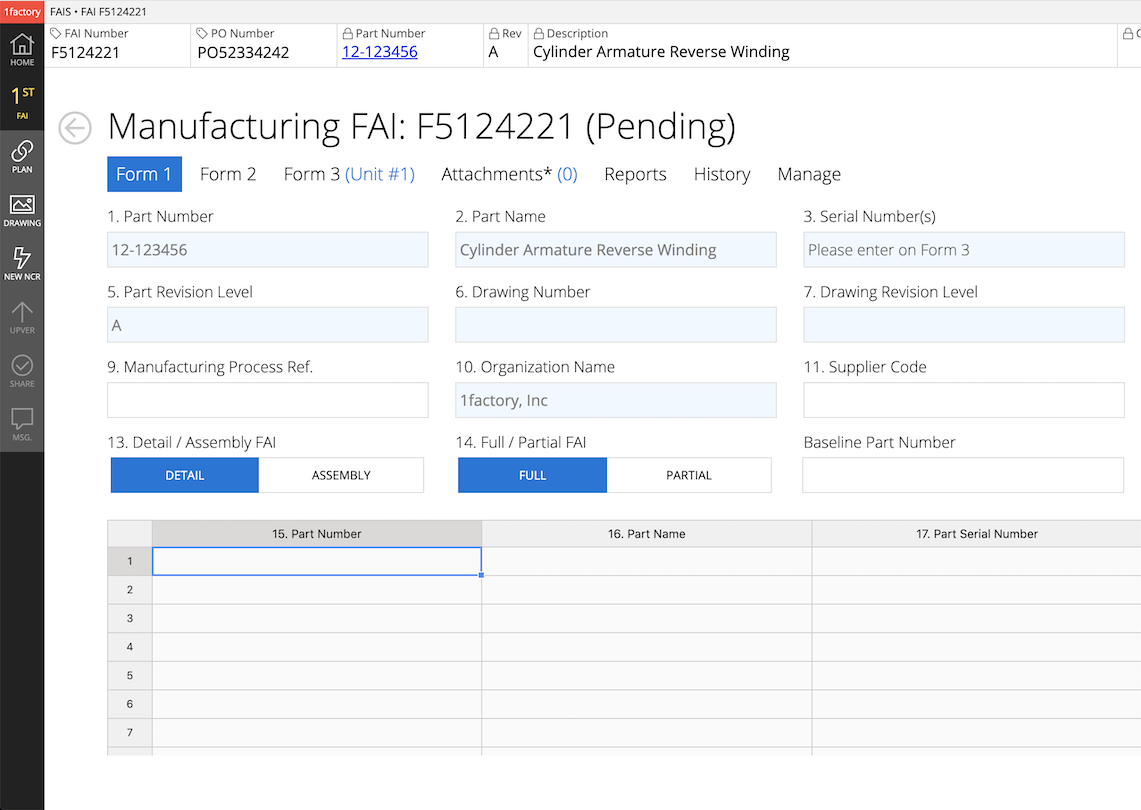

FIRST ARTICLE INSPECTION FEATURES

1 Drawing Auto-Ballooning

Auto-balloon or point-and-click to balloon drawings in minutes. Capture and extract Characteristic, Nominals, Tolerances, GD&T, Threads, Notes, Sheet Number, & Zone to a Plan with just a few clicks. Learn More

2 Automated CMM Data Import

Automate data collection from CMMs and Vision Systems. Import data from connected digital gages with the click of a button. Supported devices include Zeiss, Keyence, PCDMIS, Mitutoyo and many more.

3 FAI Reports & AS9102

Automate First Article Inspection reporting, and output a complete FAI package with dimensional reports, certs, and ballooned drawing in AS9102 and other customer specific formats. Deliver to customers electronically.

4 Internal & Supplier FAI

Digitize, standardize and simplify the FAIR process for your suppliers and for your team. Easily find and retrieve First Article Inspection records for customer or regulatory audits.

CASE STUDIES

Ultra Machining Company (UMC)- Manufacturing QC

UMC is a manufacturer of high-precision components for medical device, aerospace, and defense applications. The products are complex, with 100 — 800 features per product.

With 1factory, UMC successfully consolidated 5 separate QC systems into 1. Today, data is automatically uploaded from 20 CMMs and 8 VCMMs, 24 hours a day. Over 1 million measurements are recorded in 1factory each month. Auto-ballooning speeds up FAI creation. And hours are saved from each PPAP package creation.

Watch a 4-minute video to hear first-hand experiences from the cross-functional UMC team: Machinists, Quality Engineers, Director of Quality, VP of IT, and VP of Operations.

EASY TO USE. LIGHTNING FAST.

INTUITIVE DESIGN

1factory is designed for the front-line of quality control with design inputs and ideas from our users. 1factory's intuitive navigation and best-in-class screen-designs make training a breeze. Training and full-deployment takes under two hours with no disruption to operations.

LIGHTNING FAST SPEED

1factory is engineered to be lightning-fast. We serve customers all over the world 24 hours a day, 7 seven days a week, 365 days a year. Our customers in United States, Mexico, Canada, Israel, China, South Africa, Denmark, UK, India, Malaysia, Taiwan all enjoy lightning-fast data collection and powerful real-time analytics.

SECURE AND RELIABLE

SECURITY

1factory is hosted on AWS GovCloud. The AWS GovCloud service is an isolated Amazon region designed to host sensitive data and regulated workloads, including International Traffic in Arms Regulations (ITAR) data.

All customer data transfer from client to server is encrypted over standard HTTPS/TLS 1.2, using a certificate with 2048-bit RSA public key / SHA-256 with RSA encryption. All customer data is encrypted at rest. Data (e.g. Part Numbers, Measurements etc.) are stored in an encrypted Amazon RDS instance. Drawings, Raw Material Certificates etc. are stored on encrypted Elastic Block Storage (EBS) volumes. Drawings and other documents may be additionally encrypted with individual encryption keys.

1factory complies with all NIST-800-171 requirements. 1factory also maintains a SOC2 Type 2 certification, and a copy is available upon request.

RELIABILITY

1factory has been engineered to be highly reliable, scalable and available. Over 200 million parts have been inspected with 1factory by customers in 26 countries.

1factory has delivered an uptime of >99.99% over the last 8 years. We use a third-party service to monitor system uptime, and our customers can view our uptime and availability metrics in real time.

1factory backs-up database with a daily snapshot. Files are stored on redundant hard-drives and backed up via daily snapshots.

500+ CUSTOMERS. 25+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & DEFENSE

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS