Powerful, Easy-to-Use, Lightning-Fast

Manufacturing Execution (MES) Software. (Available: 2025)

Plan and schedule production. Build, inspect & track product through your factory. Build-up product genealogy with component identifiers including: batch code, serial number, date code, etc. Enjoy unparalleled component and assembly traceability.

KEY TRAVELER & MES FEATURES

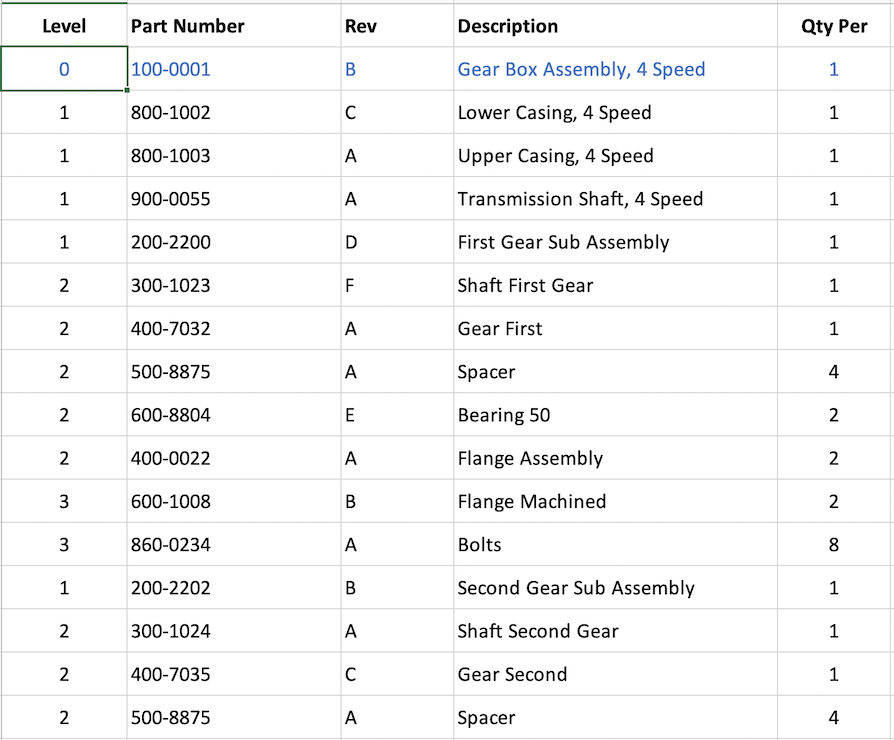

1 Parts & Bills of Materials (BoMs)

Establish master data for each part number including Quantity Used Per Assembly, Make Vs Buy, Units of Measure, ITAR requirements, and Traceability requirements. Set up Bills of Materials (BoMs) for all parts and assemblies via excel imports or integration with PLM/ERP systems.

2 Visual Work Instruction

Easily author, maintain, and release step-by-step work instructions with text and images for safety, assembly, and inspection tasks. Associate instructions with components and steps. Ensure version control of work instructions for compliance and traceability.

3 Manufacturing Process & Routing

Define manufacturing process steps and routings. Ensure compliance by defining step types: Move, inspect, safety etc.

5 Electronic Travelers

Plan production, communicate requirements to factory work centers, track production through the factory, and communicate ship dates. Capture yield and rework information. Record task completion and operator sign-offs.

6 Genealogy & Traceability

Capture product genealogy information such as Batch Numbers, Lot Numbers, Mix Numbers, Date Codes, and Serial Numbers for every component used. Easily retrieve traceability information to address customer complaints and regulatory requirements.

7 Reports & Analytics

Access real-time dashboard for monitoring work-center loading, cycle-time, yield and other performance metrics. Use data to drive operations excellence.

EASY TO USE. LIGHTNING FAST.

INTUITIVE DESIGN

1factory is designed for the front-line of quality control with design inputs and ideas from our users. 1factory's intuitive navigation and best-in-class screen-designs make training a breeze. Training and full-deployment takes under two hours with no disruption to operations.

LIGHTNING FAST SPEED

1factory is engineered to be lightning-fast. We serve customers all over the world 24 hours a day, 7 seven days a week, 365 days a year. Our customers in United States, Mexico, Canada, Israel, China, South Africa, Denmark, UK, India, Malaysia, Taiwan all enjoy lightning-fast data collection and powerful real-time analytics.

SECURE AND RELIABLE

SECURITY

1factory is hosted on AWS GovCloud. The AWS GovCloud service is an isolated Amazon region designed to host sensitive data and regulated workloads, including International Traffic in Arms Regulations (ITAR) data.

All customer data transfer from client to server is encrypted over standard HTTPS/TLS 1.2, using a certificate with 2048-bit RSA public key / SHA-256 with RSA encryption. All customer data is encrypted at rest. Data (e.g. Part Numbers, Measurements etc.) are stored in an encrypted Amazon RDS instance. Drawings, Raw Material Certificates etc. are stored on encrypted Elastic Block Storage (EBS) volumes. Drawings and other documents may be additionally encrypted with individual encryption keys.

1factory complies with all NIST-800-171 requirements. 1factory also maintains a SOC2 Type 2 certification, and a copy is available upon request.

RELIABILITY

1factory has been engineered to be highly reliable, scalable and available. Over 200 million parts have been inspected with 1factory by customers in 33 countries.

1factory has delivered an uptime of >99.99% over the last 8 years. We use a third-party service to monitor system uptime, and our customers can view our uptime and availability metrics in real time.

1factory backs-up database with a daily snapshot. Files are stored on redundant hard-drives and backed up via daily snapshots.

500+ CUSTOMERS. 30+ COUNTRIES. 20+ INDUSTRIES.

AEROSPACE & DEFENSE

AEROSPACE MACHINING

PRECISION MACHINING

MEDICAL DEVICES

AUTONOMOUS AIRCRAFT

ADVANCED CERAMICS